|

|

| |

| A: |

Our goal is to develop advanced grinding and dispersing technology and provide innovative nanomaterial and service. Become customers the most satisfied with the work partners. |

|

| |

| 2. |

What is nano grinding? Nano dispersing? |

| A: |

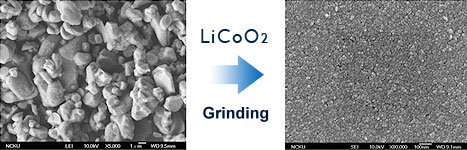

The nano grinding is to use the grinding media's shear force and Impact force that makes primary particle size from the micron and sub-micron to the nanometer level. |

|

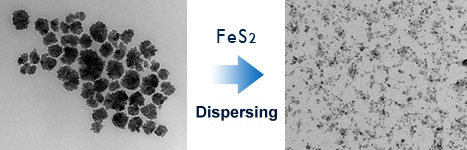

The nano grinding is to use the grinding media's shear force and Impact force and the suitable solvent, dispersing agents, that makes aggregate nano powders dispersed to a nano level uniformly. |

|

|

|

| |

| 3. |

Why choose wet grinding and dispersing equipment? |

| A: |

At present, the dry mill due to the restrictions on the design, the final particle size only to a few microns.

In addition, due to the grinding process, a large amount of energy is imported to the grinding tank that make the temperature rises rapidly and is difficult to control ; and when dry powder miniaturization, prone to dust explosion and other industrial safety related issues.

In general, if want sub-micron that nano powder, you need to use wet grinding, the wet grinding is mixing the grinding powder and solvent and dispersing agents of the original slurry uniformly, through the grinding media's shear force and impact force makes original slurry to nanometer.

Wet grinding is not only safe, more efficient access to micro or nano pastes and powders. |

|

| |

| 4. |

Why choose Yttria Stabilized Zirconia beads? |

| A: |

There are many kinds of grinding media , Yttria Stabilized Zirconia beads having a high hardness, high density, high surface stability that is most suitable grinding media for nanopowders grinding and dispersing. Ensuring the sample is not easy to pollution during the grinding process . |

|

| |

| 5. |

How to separate grinding the sample and grinding media ? |

| A: |

A:Batch:

Using Yttria Stabilized Zirconia grinding media, its density is higher than the grinding sample. After grinding , the grinding media and grinding samples density differences can be easily separated from the samples, it can also make use of simple filtration equipment separation grinding sample and grinding media.

B:Circulation:

Using gap separation or centrifugation way separation of the grinding media and grinding samples. |

|

|